Due to the modern cutting coal machine mining will produced large of coal dust , the powdery coal in market is in low value and low efficiency , only as low-level fuel processing, it caused a great of resources waste, and the powdery coal produced large of dust in storage and transit, pollution environment, so using pressure ball machine put coal powder pressure into block, instead of lump should for life live, metallurgical, chemical, carbide industry:

1.Pulverized into residents of briquettes can be used for cooking, heating and can be used for diet service used for burning.

2.In iron-smelting industry, coal, coke, iron ore, dolomite and other items according to a certain craft balls, iron, iron costs can be reduced, improving utilization and production of iron.

3.In the fertilizer industry, join the certain proportion of adhesive to anthracite, pressure the ball machine balls, can replace coal gasification, economic benefit is huge.

4.Coal briquettes can be used for lime made from plants, ceramics factory, glass factory, power plant, instead of coal, cost savings.

5.Coal, anthracite, coal, lignite and peat Burns very easily broken or cracked, so you need to use the ball machine balls adding additives to lower ash content, improved thermal stability, made into briquettes with high performance.

So the coal briquetting machine pressed into a ball can improve the added value of coal, environmental protection, energy saving, high and low pressure ball project investment as a whole benefit.

A complete coal briquettes production plant includes crusher, feeder, mixer, dryer, coal briquetting machine and conveyor. The final coal briquettes can be used as fuel and also in cement industry and other industries using boilers for steam generation. First of all, let's have a look at the flowchart of entire briquette line.

1. Rotary Dryer

Rotary dryer can be widely used to dry materials with humidity or granularity in the industries of mineral dressing, building material, metallurgy and chemical, such as metallic and nonmetallic mineral, clay in cement industry and coal in coal mine, etc. Wide supply scope and simple operation are the main features of it.

2. Compound Crusher:

Compound Crusher is designed and optimized in accordance with international latest crushing technology. It can crush all kinds of hard ores in mining, metallurgy, refractory, cement , coal, glass, ceramics, and electric power industries.Widely used in stone crushing line and sand production line, Compound Crusher is suitable for limestone, clinker, coal and other minerals of building materials, mining, metallurgy, chemical industry. Its compressive strength is not more than 140 Mpa and humidity less than 15%.

3. Feeder:

This machine is an automatic proportioning feeder which is used together with a mixer. It can automatically perform feed proportioning procedure according to the proportion setup pf customers. Besides, it can fit with one or two sets of mixers, thus improving the working efficiency. The machine is composed of feeding unit, proportioning unit, electronic control system, etc.

4. Double-shaft Mixer:

Double shaft mixer is used for mixing materials continuously and uniformly. During mixing, the raw material can be uniformly mixed with binder, and after mixed, the blended materials can be continuously sent to the conveyor. It is usually applied to mix coal, mineral powder, iron powder, coal slurry, sludge, clay, etc. Double shaft mixer has the features of high mixing speed and good uniformity.

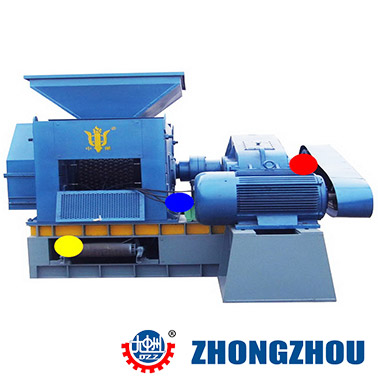

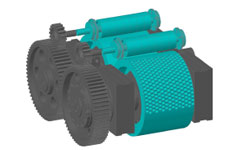

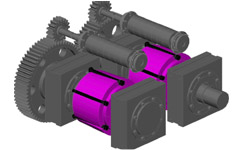

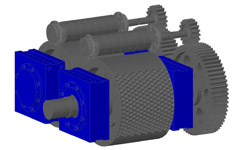

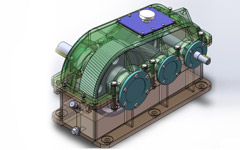

5. Coal Briquetting Machine:

Coal briquetting machine is mainly used for pressing materials with low water content such as coal powder and ore powder. Zhongzhou coal briquetting machine is a new type of briquette machine with high efficiency, energy conservancy and environmental protection. The final briquettes are smaller, energy saving, environmental friendly, and easy to transport, which make it have good economic and social benefit.

6. Mesh Belt Dryer:

The Mesh belt dryer is a kind of batch, continuous production drying equipment, mainly for better ventilation sheet, strip and granular materials, such as: preserved fruit, pepper, potato chips, cassava chips/slice, briquettes, grain straw, etc. The main types of heating include electric heating, steam heating and hot air heating.

8. Belt Conveyor:

Belt Conveyor is a kind of machine to transfer the material continuously. Its transfer capacity is high, transfer distance is long. It can work under the temperature situation ranging from -20℃ to +40℃. The temperature of transferred material by this belt conveyor should be lower than 50℃.

The requirements for raw materials of coal briquettes production:

1, the particle size of the raw material should be between 0-5mm.

2, can not contain impurities, especially large metal. Such as nails, or iron, rocks, it very likely damage roller and spindle..

3, the feeding of whole produciton line should be stable, even, ensure workloads of briquette machine stable, to get high efficiency of production.

Zhongzhou coal briquette machine is specifically designed for briquetting anthracite/ lignite coal etc coal materials, it has high productivity, high degree of automation, production efficiency,low failure rate, easy maintenance, so Zhongzhou coal briquette machine was welcomed by many enterprises at home and abroad to explore, mutual benefit and win-win.