The Main Types and Handling Materials of Drying Machine:

Drying machine can be widely used to dry various materials, such as metallic and nonmetallic mineral, clay in cement industry and coal in coal mine, etc.

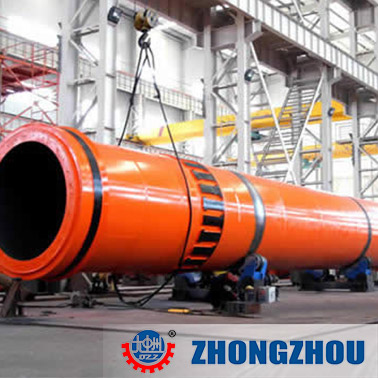

As a professional manufacturer with many years' experiences on mining machinery, Henan Zhongzhou Heavy Industry Technology Co.,Ltd can produce and supply all kinds of dryer machines, such as Rotary dryer, Limestone dryer, Drum dryer, Cement rotating dryer and so on.

The Advantages and Benefits of Drying Machine:

Reasonable design; high-efficiency; low consumption, energy consumption; easy maintenance; easy operation; quick delivery; solid construction; proven design; customized for every application; best price on the market.

The Working Process of Drying Machine:

Materials are sent to hopper of rotary dryer by belt conveyor or bucket elevator, materials enter the barrel installed with slope to horizontal line from the higher side, and hot air enters the barrel from the lower side, and then materials and hot air mix together. Materials go to the lower side by gravity when the barrel is rotating. Lifters on the inner side of barrel lift materials up and down in order to make materials and hot air mix completely, which is designed to improve the producing efficiency of rotary dryer.