Zhongzhou wet press briquette machine is mainly used to press the lignite, coal, iron concentrate, aluminum powder, coke, iron oxide, carbon powder, carbon powder, slag, gypsum, tailings, sludge, kaolin, activated carbon, other ore powder, widely used in refractories, metallurgy, chemical industry, power plants, energy, transportation, heating and other industries, the briquettes be pressed by wet press briquette machine is energy saving and environmental protection, convenient transportation, improve the utilization rate of waste, with advantages of continuous production, high automation, good economic and social benefits.

Statement of the Complete Output 2-50 T/H Briquettes Production Line

1. Rotary Dryer

Rotary dryer is widely used to dry humidity granularity materials in the industries of mineral dressing, building material, metallurgy and chemical, coal mine, etc. Wide supply scope and simple operation are the main features of it, materials should be dried to 3-10% water content that meet the demands of briquetting.

2. Two Stage Crusher:

Two stage crusher is designed and optimized in accordance with international latest crushing technology. It can crush all kinds of hard ore/metallurgy materials such as limestone, clinker, coal,coke,manganese, silica, iron ore, zinc oxide etc minerals in the metallurgy, mining, chemical industry. Its humidity of raw materials can be reach to 40%,the feeding size reach to 400mm, after crushing, the particle not more than 3mm to meet briquetting.

3. Hopper silo: This is an automatic proportioning feeder which is used together with next mixer. It can automatically perform feed proportioning procedure according to the proportion setup pf customers so that improve working efficiency. That is composed of feeding unit, proportioning unit, electronic control system, etc.

4. Horizontal Two-shaft Mixer:

The horizontal two- shaft mixer mix materials continuously and uniformly. During the mixing, to add water and binder (liquid binder or powderd binder is considered by user's formula),controlling moisture in 8-15%,then the blended materials continuously go into briquette machine for briquetting by belt conveyor,

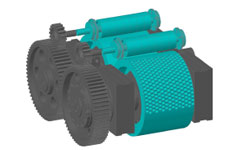

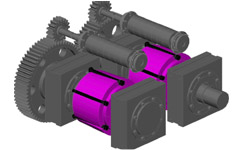

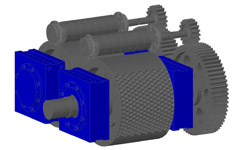

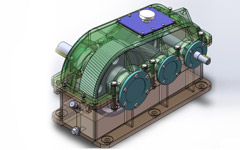

5. Wet Press Briquette Machine:

Zhongzhou wet briquette machine is a new patented type of briquetting machine, easy to operate, high pressure, work stably, energy conservantion, environmental friendly, easy for user to remove and install, mould can be produced in accordance with customer's requirements, the final briquettes has high hardness, high density, espcially the thermal intensity is high.

6. Vertical Dryer:

This is the professional equipment for drying briquettes, no matter coal briquettes, mineral briquettes,metallurgy briquettes, all can be dried by this vertical dryer, the moisture content of briquettes can be reduced to 3%, cause of briquettes came from briquette machine with 12% water content, using a drying equipment is necessary for a large scale project. Vertical dryer has the advantages of continuous production, small occupation area, low energy consumption, less parts, low failure, high yield, it is a customer preferred drying equipment.

7. Belt Conveyor:

This belt conveyor transfers material into every equipment, make the whole production line work continuously and automatically. It works under the temperature situation ranging from -20℃ to +40℃, the transferred material should be lower than 50℃.

8. Electric control cabinet

Its main role is for the all motors' start and stop control in the whole production line, under the special requirement it's also able to control the position of the motor and the speed, fault detection and fault diagnosis can be carried out when the motor is in fault, which is very convenient and quick.

Different materials will be designed into different production solution, customer at the time of consultation need inform us of the materials' moisture, particle size, yield, briquettes size, shape, some special circumstances maybe need auxiliary equipment such as other types of crusher,other types of mixer,screen mesh, vibration sieve, binder feeder, liquid mixing tank, magnetic separator, electronic belt weigher, variable-frequency drive.

If you would like to get more information about wet press briquette machine, please consult with us by e-mail or by online hnzzkj@dzzzg.cn, +86-371-64397666 , +86-18703866697/18539955836.